|

As a key part of this design philosophy, the D-Tek™ System introduces a next-generation technique of chassis and body construction. Moving beyond the limitations of steel or aluminum frame, unibody, and other structural concepts, the D-Tek™ System encompasses a broad range of technologies. At its heart is the honeycomb sandwich panel, first introduced to reduce weight in aircraft while still providing superior structural strength and longevity compared with traditional wood, steel, and aluminum. By reducing structural weight, the aerospace industry was able to improve maneuverability, payload capacity, range, and fuel economy, advantages that have proven useful in other applications ranging from elevators and telescopes to building construction and commercial truck trailers. The DiMora Motorcar D-Tek™ System brings the full benefits of honeycomb panel structures to automotive chassis and body construction while pioneering a structural manufacturing system applicable to diverse industries. By providing a standard set of techniques to enable engineers in various fields to explore new applications, DiMora Motorcar enables engineers to take advantage of the many benefits of D-Tek™ panels, such as reducing weight while adding stiffness and strength. D-Tek™ panels also address strict requirements to suppress fire and smoke—critical in air travel and automobiles—as well as reducing noise and vibration. From satellite platforms, to automotive chassis and bodies, to wall and ceiling structures, to countertops, the uses of this technology are unlimited. For this reason, DiMora Motorcar is making the D-Tek™ System available on an industry-wide basis. D-Tek™ honeycomb core materials offered currently include aluminum, titanium, and Nomex, while facing options include lava rock materials, carbon fiber, aluminum, and fiberglass. Many other core and facing materials can be specified to meet a client’s requirements for strength, weight, insulation, features, and cost. Engineers may select thicker or thinner facing sheets, different alloys, specific anodized treatments to aluminum, multiple layers of fiberglass or carbon fiber, or multiple types of core cell patterns and sizes, in different densities, thicknesses, etc., to meet virtually any design requirement. A Paradigm Shift in Automotive Manufacturing The Traditional Ways to Build an Automotive Chassis • Steel I-beam chassis, steel tube space frame, or unibody construction using steel or aluminum. The DiMora D-Tek™ Way to Build an Automotive Chassis • Produce panels of precise dimensions, including slots for joining with other panels. Benefits of the DiMora D-Tek™ System • A D-Tek™ chassis is remarkably lightweight. For example, the Natalia SLS 2 chassis weighs 457 pounds, at a length of 250 inches. A steel frame chassis of this size would normally weigh around 1900 pounds. (See D-Tek™ Material Properties below.) Effective Management of Body Design and Class A Surfacing Note: "Class A surface" is a term used in automotive design to describe a set of freeform surfaces of extremely high efficiency and quality. Although, strictly, it is nothing more than saying the surfaces have curvature and tangency alignment to ideal aesthetical reflection quality. Class A surface modelers are also called "digital sculptors" in the industry. Industrial designers develop their design styling through the A surface, the physical surface the end user can feel, touch, see etc. A common method of working is to start with a prototype model and produce smooth mathematical Class A surfaces to describe, for examples, an automobile's outer body, hood, or dashboard. From this the production of tools and inspection of finished parts can be carried out. Class A surfacing complements the prototype modeling stage by reducing time and increasing control over design iterations. • Body is fully designed, using computer-aided design (CAD) programming tools. Additional Benefits of the D-Tek™ System • Insulation. This is especially important in relation to air conditioner usage in summer, and less important for winter heating as most internal combustion engines have sufficient excess heat for passenger comfort purposes. However, electric cars do not have this ready source of heat, so for them, winter insulation is also important. Example D-Tek™ Material Properties D-Tek™ panels may be constructed with a wide variety of core and facing materials, thicknesses, insulating materials, etc. The following chart is an example showing the specifications for one particular type of one-inch thick panel used in the D-Tek™ System that happens to have an aluminum core with composite skin.

|

|

Sheet Material Property |

Test Method |

Units |

Value |

|

Thickness |

ASTM C366 |

inch |

1.000 |

|

Weight |

ASTM C29 |

lbs/sq ft |

.71 |

|

Temperature Resistance |

n/a |

degrees F |

250 |

|

Long Beam Flexural Facing Stress @ Failure |

MIL-STD-401B |

psi |

30,000 |

|

Deflection @ 100 lb. Load |

MIL-STD-401B |

inch |

0.120 |

|

Flatwise Tension (Ultimate Stress) |

MIL-STD-401B |

psi |

300 |

|

Edgewise Compression (Max Load) |

MIL-STD-401B |

psi |

2,500 |

|

Flatwise Compression |

MIL-STD-401B |

psi |

340 |

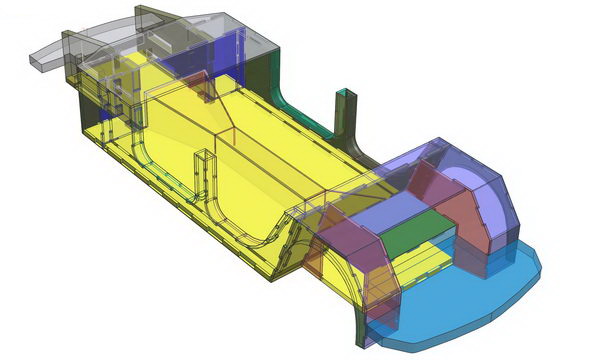

The D-Tek™ chassis configuration of the Natalia SLS 2.

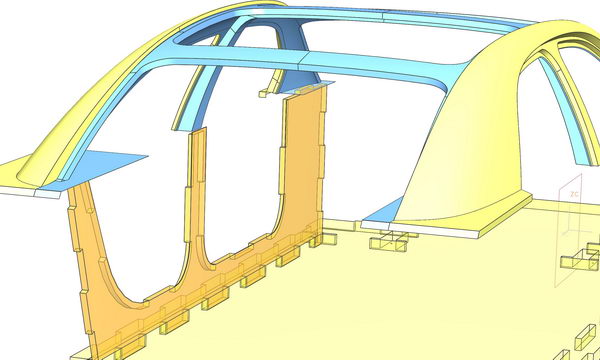

The D-Tek™ chassis interlocking panels.

† |